- St. Petersburg

- Promyshlennaya St., 19R

- +7 (812) 602-52-94

- Moscow

- Novgorodskaya St., 1

- +7 499 647-54-32

- Volgograd

- Mira St., 19

- +7 844 268-48-25

- Voronezh

- Moskovsky prospect, 4

- +7 473 201-60-99

- Екатеринбург

- Антона Валека ул., д. 13

- +7 343 302-00-42

- Kazan

- Protochnaya St., 8

- +7 843 207-28-35

- Krasnodar

- Karasunskaya St., 60

- +7 861 211-72-34

- Krasnoyarsk

- Vzletnaya St., 57

- +7 391 229-59-39

- Nizhny Novgorod

- Maxima Gorkogo St., 260

- +7 831 288-54-50

- Novosibirsk

- Garanina St., 15

- +7 383 312-14-04

- Orenburg

- Shosseynaya St., 24A

- +7 353 248-64-94

- Perm

- Arkadia Gaidara St., 8B

- +7 342 233-83-04

- Rostov-on-Don

- Maxima Gorkogo St., house 295

- +7 863 309-21-51

- Samara

- Sklyarenko St., 26

- +7 846 215-16-17

- Surgut

- 30 Let Pobedy St., 44B

- +7 346 276-92-88

- Tyumen

- Permyakova St., 1

- +7 345 256-43-32

- Ufa

- Kirova St., 107

- +7 347 225-34-97

- Khabarovsk

- Karla Marksa St., 96A

- +7 421 252-90-77

- Chelyabinsk

- Pobedy Prospekt., 160

- +7 351 225-72-62

- Yakutsk

- Korolenko St., 25

- +7 411 250-55-80

- Yaroslavl

- Nekrasova St., 41A

- +7 4852 27-52-34

Diesel genset control panels and remote monitoring

The genset control panel is equipped with digital controllers, which fulfill the functions of control, security, visualization and automation of operation, implement genset diesel start/stop manually or automatically, protect against a high coolant temperature condition, from oil depressurization in the oil system.

A standard set of DG control panel functions:

- DG control: start/stop, genset operation mode switching.

- Genset operation visualization: power, voltage, current, frequency.

- Visualization of engine operation: temperature, oil pressure, fuel level in the tank, battery voltage, engine speed.

- Engine protection: low oil pressure, high coolant temperature, low coolant level, high/low engine speed, invalid fuel level, invalid battery voltage.

- Generator protection: high/low voltage, overcurrent/power, phase load unbalance, generator high/low frequency, insulation fault protection.

- Statistics: operating hour meter, meter of time until next maintenance, energy consumption meter, error history.

Extra options:

- DG autostart.

- ATS unit control (load switching).

- synchronization between several generators or the generator and mains.

- DG remote monitoring.

- DG remote control.

- engine heating control.

- the interface of diagnostics and communication of the control panel and engine control unit (CAN bus)

- interfaces for connecting additional DG control modules (RS232, RS485, USB, LAN).

The most popular manufacturers of control systems for power plants are ComAp (Czech Republic) and Deep Sea Electronics (DSE, Great Britain).

ComAp control panels for diesel generators

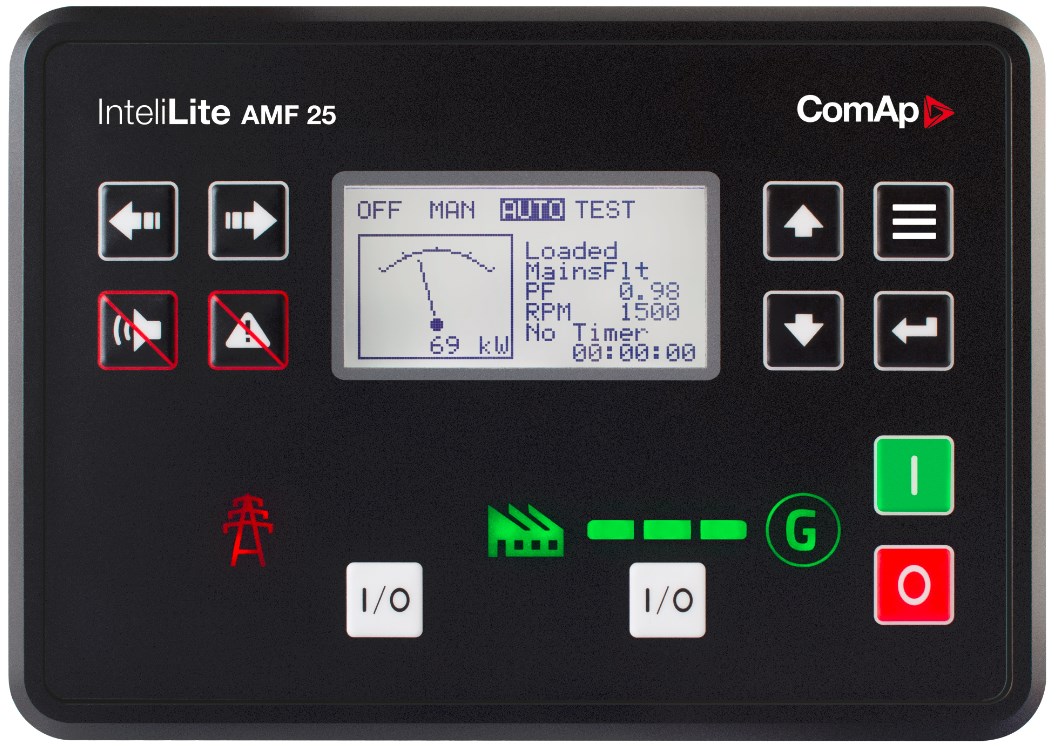

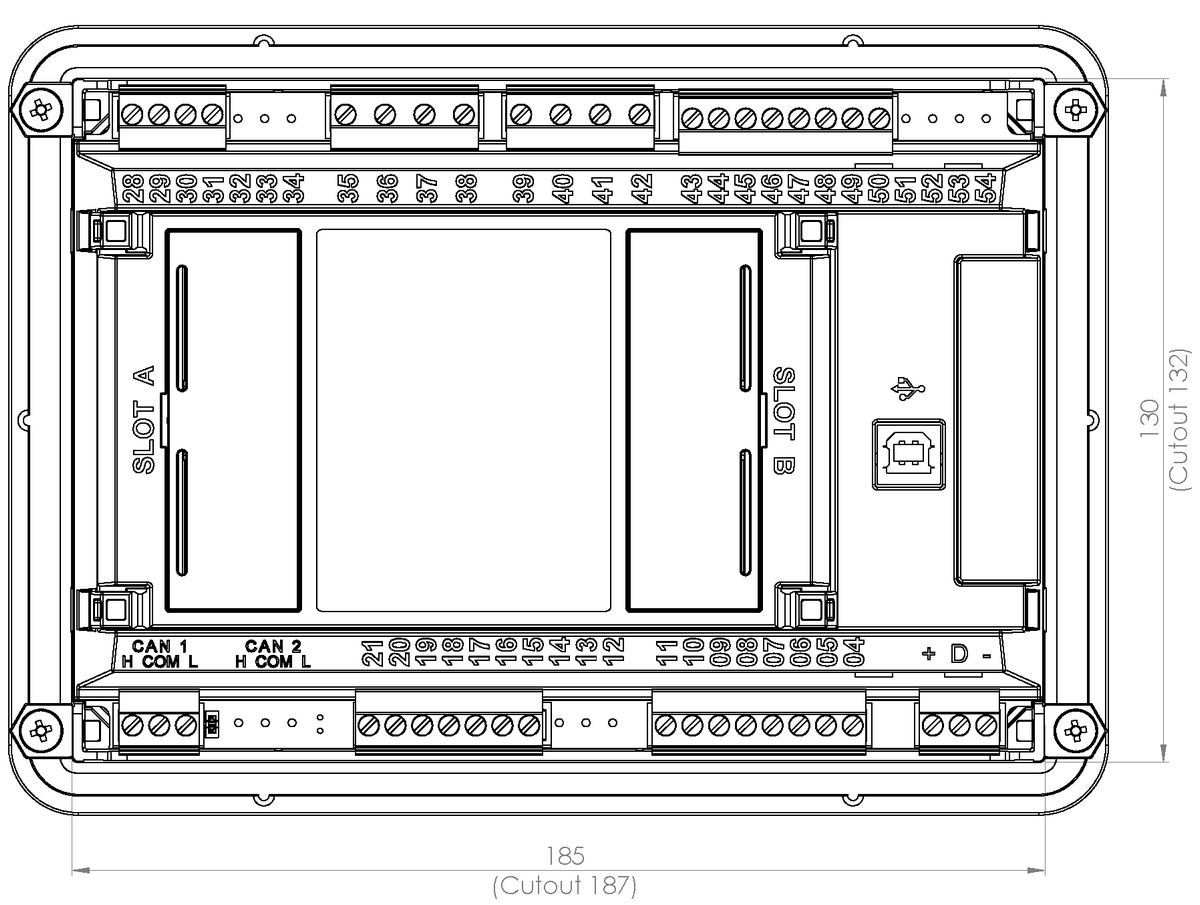

InteliLite NT – a family of controllers ensuring security, monitoring and control of medium- and high-capacity generators. The controller offers many extension and communication functions with additional units. Two versions are available: MRS (manual remote start) and AMF (automatic start).

InteliLite AMF 25 – the most popular panel for DG.

|

|

Controllers for the parallel operation of diesel gensets:

InteliGen NT - main controller for one and several DGs operating in back-up or parallel mode.

MainsCompact NT and InteliMains NT BaseBox are intended for several (up to 31) gensets operating in parallel with the mains. InteliMainsNT BaseBox is compatible with InteliGenNT and InteliSysNT.

InteliCompact NT is intended for simple single and group applications requiring ATS functions, parallel operation and load distribution. The standard set of functions includes a protocol for communication with electronic engines via J1939 и CAN BUS.

InteliGen 200 is a controller for gensets operating both in backup and parallel modes. User-friendly functionality, simple configuration and installation, as well as the functions of automatic synchronization and load distribution.

InteliGen 500 is an advanced controller with a color monitor for generator units in backup and parallel mode.

InteliCompact NT – OPERATOR MANUAL, genset controller for parallel operation.pdf

InteliGen 200 Controller for parallel use of gensets.pdf

Deep Sea (DSE) control panels

DSE8610 Controller User manual.pdf

Operator manual for “DSE 7000” series control and measurement systems.pdf

Operator manual for 8620 series DSE model control systems and equipment.pdf

Dispatching diesel generators

The diesel genset remote monitoring and control system allows the operator to remotely control all diesel genset parameters, start/stop it and fulfill other functions, which are compatible with the diesel genset remote control console.

Monitoring functions: remote transfer of the parameters of the diesel genset, transmission of warning and emergency signals and signals of a fire and security alarm installed in the container.

Control functions: remote control of all functions of the diesel genset via the remote control console.

Versions of remote monitoring and control systems:

Monitoring and control via the Internet: it allows controlling the genset and monitoring the parameters of the technical status of the unit using an internet connection established between the diesel genset and a PC operator.

Monitoring and control via GSM mobile communications: connecting the diesel genset and the operator's computer/controller is implemented via RS232 channel using a GSM model. The data transmission function (CSD) shall be connected, 2 SIM cards are installed: at the site and at the operator. Information on the status of diesel genset systems is transferred not only to the operator's computer but also as SMS to the selected phone number.

Monitoring and control via Ethernet: a system via Ethernet communication channel allows controlling the operation of the diesel genset within a local network. Data on the status and operation modes are transferred to the operator’s computer, control is implemented from it too. Operating range - up to 300 m with the possibility of expansion using a switch.

Monitoring and control via wiring channel (via CAN bus): wired communication between the DG and the operator's computer/controller using wires. Operating range - no more than 1 km.

Thanks to the remote monitoring system, the operation of the diesel generator can be controlled using software from a computer or smartphone. When the notification function via SMS is enabled, a message will be received stating that the generator accepts the load, and turns off.

-

Diesel generators

40-100 kW -

Diesel generators

300-500 kW -

Diesel generators

1000-1200 kW -

Diesel generators

1600-1800 kW -

Diesel generators

150-250 kW -

Diesel generators

600-800 kW -

Diesel generators

1300-1500 kW -

Diesel generators

2000-2500 kW

- Diesel generators for up to 1 million rubles.

- Diesel generators for up to 1.5 million rubles.

- Diesel generators for up to 2 million rubles.

- Diesel generator sets for 2-3 million rubles.

- Diesel generator sets for 3-4 million rubles.

- Diesel generator sets for 4-5 million rubles.

- Diesel generator sets for 5-7 million rubles.

- Diesel generator sets for 8-10 million rubles.

- Diesel generator sets for 10-12 million rubles.

- Diesel generator sets for 13-15 million rubles.

- Diesel generator sets for 15-18 million rubles.

- Diesel generator sets for 18-20 million rubles.