- St. Petersburg

- Promyshlennaya St., 19R

- +7 (812) 602-52-94

- Moscow

- Novgorodskaya St., 1

- +7 499 647-54-32

- Volgograd

- Mira St., 19

- +7 844 268-48-25

- Voronezh

- Moskovsky prospect, 4

- +7 473 201-60-99

- Екатеринбург

- Антона Валека ул., д. 13

- +7 343 302-00-42

- Kazan

- Protochnaya St., 8

- +7 843 207-28-35

- Krasnodar

- Karasunskaya St., 60

- +7 861 211-72-34

- Krasnoyarsk

- Vzletnaya St., 57

- +7 391 229-59-39

- Nizhny Novgorod

- Maxima Gorkogo St., 260

- +7 831 288-54-50

- Novosibirsk

- Garanina St., 15

- +7 383 312-14-04

- Orenburg

- Shosseynaya St., 24A

- +7 353 248-64-94

- Perm

- Arkadia Gaidara St., 8B

- +7 342 233-83-04

- Rostov-on-Don

- Maxima Gorkogo St., house 295

- +7 863 309-21-51

- Samara

- Sklyarenko St., 26

- +7 846 215-16-17

- Surgut

- 30 Let Pobedy St., 44B

- +7 346 276-92-88

- Tyumen

- Permyakova St., 1

- +7 345 256-43-32

- Ufa

- Kirova St., 107

- +7 347 225-34-97

- Khabarovsk

- Karla Marksa St., 96A

- +7 421 252-90-77

- Chelyabinsk

- Pobedy Prospekt., 160

- +7 351 225-72-62

- Yakutsk

- Korolenko St., 25

- +7 411 250-55-80

- Yaroslavl

- Nekrasova St., 41A

- +7 4852 27-52-34

DGS of 50/400/520/1200 kW, installation of foundations, laying of a cable route, modernization of VRU-3/RU-04 and automation for Kaliningradteploset

| Total capacity | 2690 kW |

| Client | Kaliningradteploset municipal enterprise |

| Фото | |

| Task |

Providing the uninterruptable power supply of heating energy sources |

| Solution |

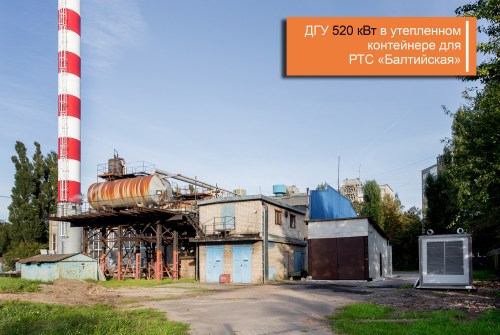

In fall 2019, the project for providing Kaliningradteploset municipal enterprise with power equipment was completed. Kaliningradteploset ME is the largest Kaliningrad thermal energy producer and supplier. The extensive 686 long network of thermal energy transportation covers all regions of the city. In total, including built-in coal boiler-rooms, there are 74 heat supply sources, among which eight 595 Gcal-hr regional heating stations using natural gas as the main fuel type. Our task was to provide the uninterruptable power of heating energy sources – 4 regional heating stations and service water station Pribrezhny. In addition to delivering the equipment, our team executed building works and earthwork operations to route cables and connect the electrical plant into the existing power supply scheme. Equipment delivered: The total capacity of the power equipment delivered – 2 690 kW. The diesel gensets were designed and engineered individually for every site.

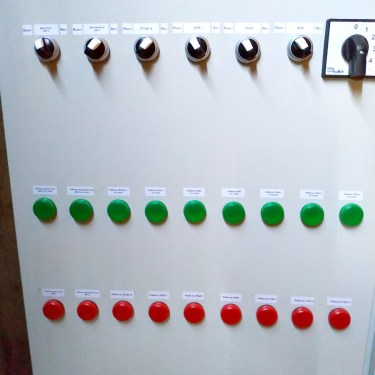

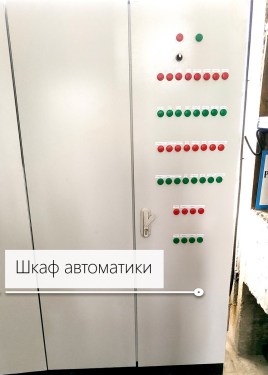

The diesel gensets are installed in Techexpo own-produced heat-insulated containers. The first degree of plant automation involves the manual start and connection of consumers. However, the diesel generator is started up and stopped remotely from the transformer plant the diesel generators are connected to. To implement the solution, we modernized electrical facilities at the following plants:

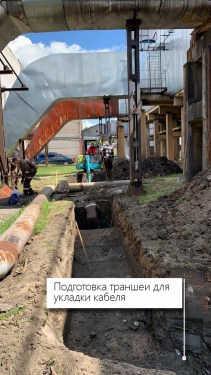

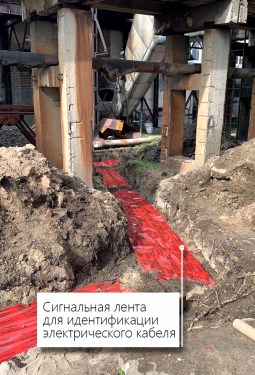

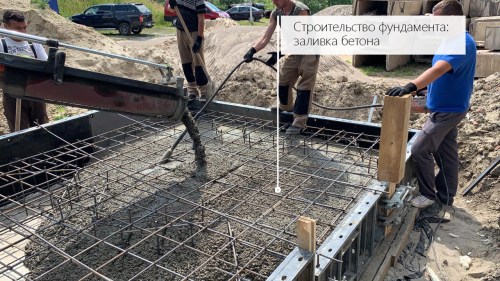

New cabin electrical equipment was installed for every facility: - a power cabinet for switching between mains and the diesel generator sets; - control cabinets, which allow the operator to remotely connect vital consumers to the diesel genset from his workplace. Construction / installation activities: Based on a project approved by Kaliningradteploset ME, we selected equipment and carried out installation and construction works to organize external cable run and install the foundation. Earthwork operations started with the foundation: - soil excavation, sand base bottoming, concrete bedding, foundation reinforcing, concrete pouring, two-layer membrane bituminous waterproofing; - to make the earth loop foundation, a steel galvanized strip in the form of a closed ring was first laid. The materials and work procedure correspond to the rules and regulations SP 45.13330.2017 ‘Earthworks, foundation engineering’. Revised edition of Construction code and regulations 3.02.01-87". The next stage is cable routing from the diesel genset to the genset. The distance between them differs depending on a particular site – from 25 to 60 meters.

The total length of the implemented cable run for all sites was 145 meters. All the works are done according to SP 126.13330.2012 ‘Survey operations in construction’. Inside the premises, we carried out connections with all existing cable structures. On the Baltiyskaya regional heating station, we installed a special structure for routing cables across the outer wall of the building. Also, diamond drilling of horizontal openings in armored concrete floors was carried out to route cables inside the premises. When the construction installation works were completed and the diesel generator was connected, our specialists carried out pre-commissioning activities – the final stage of the work. The Techexpo service department has necessary access permits and equipment for carrying out acceptance tests in accordance with the requirements of GOST – an electrical laboratory licensed by the Russian Federal Service for Ecological, Technical and Atomic Supervision to carry out diesel genset tests. |

Order the budget estimation for a similar project - make a request to order+35836@tech-expo.ru

We’ll send an engineer to your site for free pre-project inspection, select equipment, develop the budget.

-

Diesel generators

40-100 kW -

Diesel generators

300-500 kW -

Diesel generators

1000-1200 kW -

Diesel generators

1600-1800 kW -

Diesel generators

150-250 kW -

Diesel generators

600-800 kW -

Diesel generators

1300-1500 kW -

Diesel generators

2000-2500 kW

- Diesel generators for up to 1 million rubles.

- Diesel generators for up to 1.5 million rubles.

- Diesel generators for up to 2 million rubles.

- Diesel generator sets for 2-3 million rubles.

- Diesel generator sets for 3-4 million rubles.

- Diesel generator sets for 4-5 million rubles.

- Diesel generator sets for 5-7 million rubles.

- Diesel generator sets for 8-10 million rubles.

- Diesel generator sets for 10-12 million rubles.

- Diesel generator sets for 13-15 million rubles.

- Diesel generator sets for 15-18 million rubles.

- Diesel generator sets for 18-20 million rubles.