- St. Petersburg

- Promyshlennaya St., 19R

- +7 (812) 602-52-94

- Moscow

- Novgorodskaya St., 1

- +7 499 647-54-32

- Volgograd

- Mira St., 19

- +7 844 268-48-25

- Voronezh

- Moskovsky prospect, 4

- +7 473 201-60-99

- Екатеринбург

- Антона Валека ул., д. 13

- +7 343 302-00-42

- Kazan

- Protochnaya St., 8

- +7 843 207-28-35

- Krasnodar

- Karasunskaya St., 60

- +7 861 211-72-34

- Krasnoyarsk

- Vzletnaya St., 57

- +7 391 229-59-39

- Nizhny Novgorod

- Maxima Gorkogo St., 260

- +7 831 288-54-50

- Novosibirsk

- Garanina St., 15

- +7 383 312-14-04

- Orenburg

- Shosseynaya St., 24A

- +7 353 248-64-94

- Perm

- Arkadia Gaidara St., 8B

- +7 342 233-83-04

- Rostov-on-Don

- Maxima Gorkogo St., house 295

- +7 863 309-21-51

- Samara

- Sklyarenko St., 26

- +7 846 215-16-17

- Surgut

- 30 Let Pobedy St., 44B

- +7 346 276-92-88

- Tyumen

- Permyakova St., 1

- +7 345 256-43-32

- Ufa

- Kirova St., 107

- +7 347 225-34-97

- Khabarovsk

- Karla Marksa St., 96A

- +7 421 252-90-77

- Chelyabinsk

- Pobedy Prospekt., 160

- +7 351 225-72-62

- Yakutsk

- Korolenko St., 25

- +7 411 250-55-80

- Yaroslavl

- Nekrasova St., 41A

- +7 4852 27-52-34

1 MW diesel genset with a voltage of 6,3 kV for a Goznak JSC branch in Saint Petersburg

| Total capacity | 1000 kW |

| State order | State procurement documentation |

| Client | Saint Petersburg paper factory – a Goznak JSC branch |

| Фото | |

| Solution |

In December 2019, we completed an emergency power system based on a 1 MW diesel genset with a voltage of 6,3 kW for a Goznak JSC branch - Saint Petersburg paper factory. The diesel genset powers the factory’s life support facilities and machine operation when there’s no mains voltage. We carried out a pre-plan study, design, equipment delivery, construction and installation works, pre-commissioning and erection supervision works, as well as obtained a permit from Rostechnadzor (Russian Technical Supervision Service) to put the genset in operation. DesigningTechexpo is a member of a self-regulated organization and has a right to execute design documentation. We developed design estimate documentation for emergency power supply on the basis of a diesel generator under the Goznak JSC technical specifications guiding by applicable regulatory documents: Electrical installation code, edition 6-7, Town mains design code RD 34.20.185-94, System of Design Documentation for Construction GOST Р21.1101-2009, Decree of the Russian Government #87 from 16.02.08 Regulation on Composition of Design Documentation Sections and Requirements to Their Contents, Decree of the Russian Department of Labor #74n from February 19, 2016 Safety rules when operating electrical plants, SP 76.13330.2016 Electrical devices.

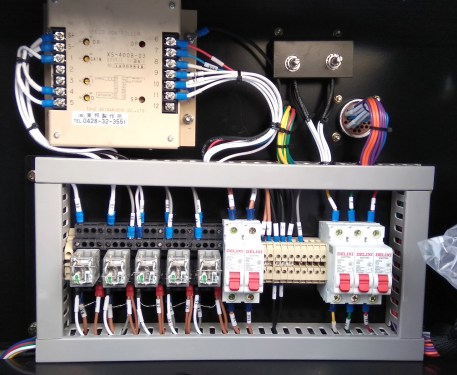

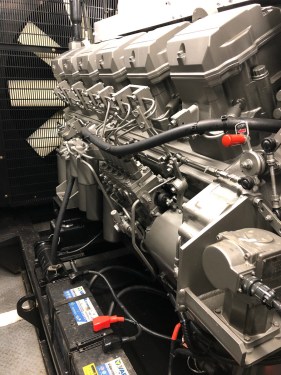

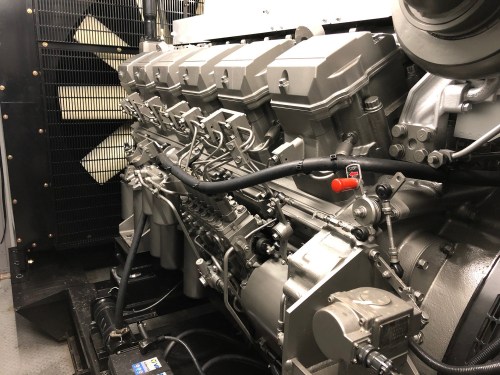

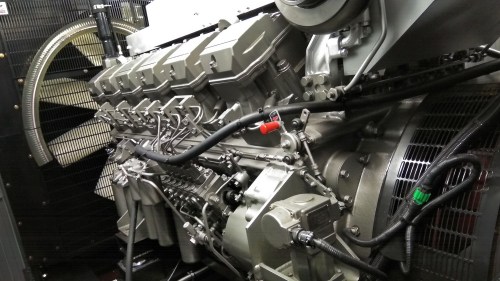

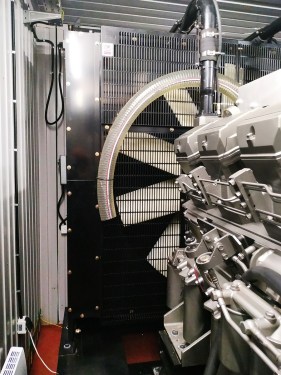

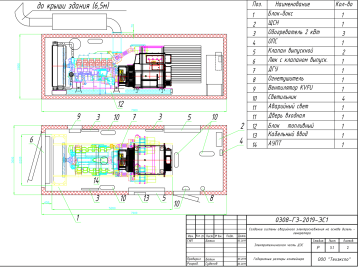

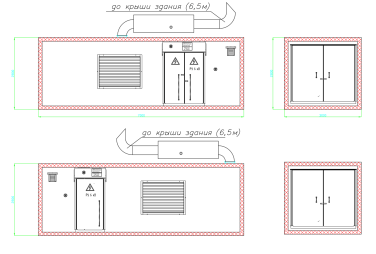

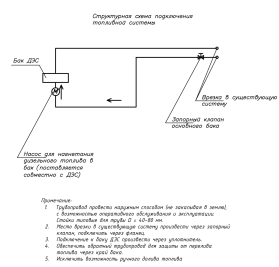

The genset location, diesel genset model and design, connection method were determined. A 1000 kW HV diesel genset will operate as a redundant power supply and start only when the mains voltage is lost. The diesel genset will not operate in parallel with mains; the switch is manual. The containerized diesel genset is mounted on a foundation plate outdoors nearby the factory building. The container consists of the next systems:

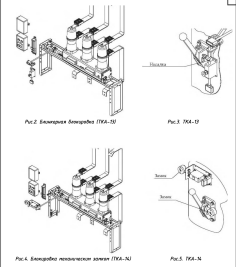

The project provides for fixed load redundancy at the high-voltage side of three transformer substations. To this end, the reconstruction of two of three transformer substations is required – modernization (retrofit) of switching high-voltage cells. In this case, it means the introduction of modern equipment with overcurrent and cutoff functions into existing bodies of HV cells KSO-272 and KSO-292 (switchgear of unilateral maintenance): SM15_LD_1(48) vacuum circuit-breaker, CM-16-1 control unit, BMRZ-152-2-D-VV-01 (relay protection microprocessor unit) safety and automation device. Choosing high-voltage equipment for the project allowed significantly cutting expenses for cables: at a length of 3000 m, savings amounted to 4000 rubles per 1 running meter. The use of a common 400 V diesel genset would require a heavy section and long copper cable, which would additionally increase expenses by 12-15 million rubles only for cables. Based on a topographic plan, we designed laying 6 kV cable lines in the ground and over cable structures inside and outside the building. Brand and section were determined based on the calculation of 6 kV cable line performance, overload factor and 1000 kW diesel genset nominal rating. Estimate documentation – a final stage of the project. An estimate was made for earthwork and construction operations for pre-cabling and cable line installation, assembly operations, site improvement, installation of a diesel genset on a container and foundation construction, an estimate for power equipment, cell retrofit installation works and pre-commissioning activities. Project implementationEquipmentA 1 MW diesel genset with a Mitsubishi S12R-PTA engine and a Leroy Somer LSA52.2L45 current generator with a voltage of 6,3 kV. A 1000-liter fuel tank. The diesel genset is housed in a Techexpo own-produced heat-insulated all-metal container. The container comes with a fire alarm and fire suppression system, a heating system, lighting and ventilation systems. The diesel genset auxiliaries board is also placed in the container and provides all container systems with power. The diesel genset operation is monitored using a Сomap AMF25 controller. The gas exhaust system consists of a muffler, a discharge and a flexible compensator provided by the diesel genset manufacturer, and a metal rain-proof discharge. Earthwork and construction operations:Before diesel genset installation, we laid cable lines and prepared the foundation. According to clauses 1.5, 1.6, 2.5 of Building codes and regulations 2.02.05-87. 'Foundations of machines with live load' the diesel genset foundation was separated from the existing building foundation. Also, its design provides vibration insulation and a reinforced concrete layer. 3 000 meters of cable lines were laid. Laying cable lines was carried out in the ground and over cable structures inside and outside the building. The works were executed according to Instruction #2-02 for Laying Power Cables to 35 kV approved by the Saint Petersburg Cable network, 1991. Trenches for cable lines were provided:

Installation worksThe diesel genset is housed in a container in the inner plant yard. The diesel genset is grounded by connecting a steel strip from a point on the diesel genset with an existing ground loop of the boiler house building. The diesel genset fuel tank volume is 1000 liters. This is sufficient for 4 hours of autonomous operation. We provided more time by connecting the diesel genset fuel system to the existing diesel fuel supply system: we laid pipeline with the external method (available for prompt service and operation) except for a 2-meter section from the boiler house building to the diesel genset. Reconstructing two cells of transformer substation’s 6 kV switchgearThe modernization of high voltage cells KSO-272 and KSO-292 (switchgear of unilateral maintenance) was required to connect the diesel genset to each transformer substation according to technical specifications. The dimensions of the cells are the same, that’s why a fitting kit is identical for both cells. We installed a BB/TEL vacuum circuit-breaker into the cells of switchgears of unilateral maintenance. To control circuit-breakers in these cells, BU/TEL-05A control units with BP/TEL-220-02A power units are used in these cells. We connected circuit-breakers to the main circuit and their control circuit in relay protection and cell automatics circuit. The cell provides mechanical blocking between breakers and grounding disconnectors. Following the retrofit, the location and purpose of all existing switching elements except breakers remained the same. A Mercury 230 ART-03 meter was installed on every cell and commercial electricity metering was organized.

|

Order the budget estimation for a similar project - make a request to order+35836@tech-expo.ru

We’ll send an engineer to your site for free pre-project inspection, select equipment, develop the budget.

-

Diesel generators

40-100 kW -

Diesel generators

300-500 kW -

Diesel generators

1000-1200 kW -

Diesel generators

1600-1800 kW -

Diesel generators

150-250 kW -

Diesel generators

600-800 kW -

Diesel generators

1300-1500 kW -

Diesel generators

2000-2500 kW

- Diesel generators for up to 1 million rubles.

- Diesel generators for up to 1.5 million rubles.

- Diesel generators for up to 2 million rubles.

- Diesel generator sets for 2-3 million rubles.

- Diesel generator sets for 3-4 million rubles.

- Diesel generator sets for 4-5 million rubles.

- Diesel generator sets for 5-7 million rubles.

- Diesel generator sets for 8-10 million rubles.

- Diesel generator sets for 10-12 million rubles.

- Diesel generator sets for 13-15 million rubles.

- Diesel generator sets for 15-18 million rubles.

- Diesel generator sets for 18-20 million rubles.